- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-14 Origin: Site

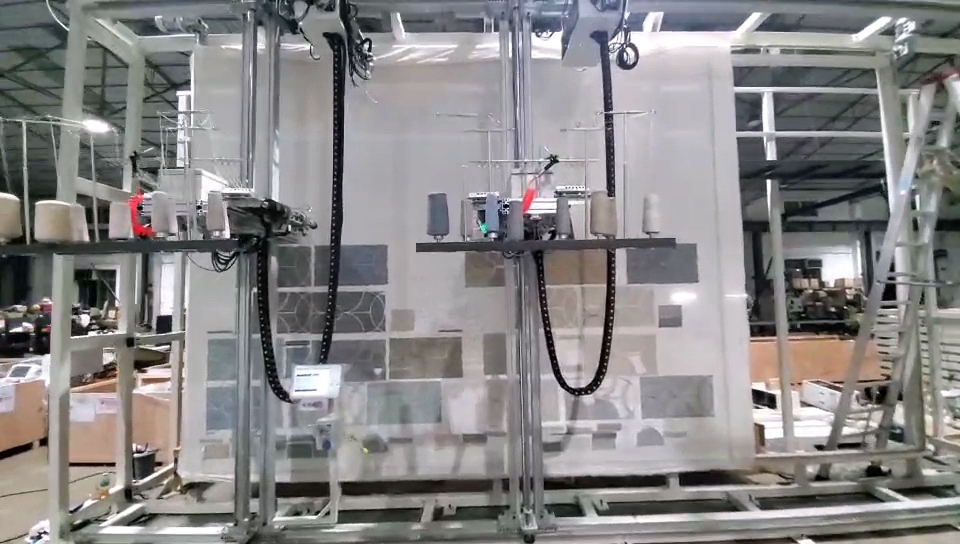

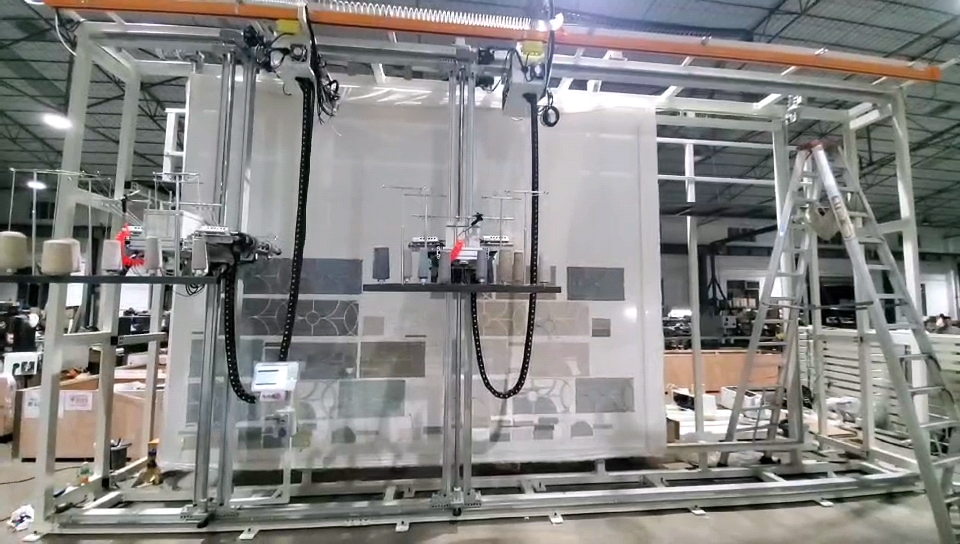

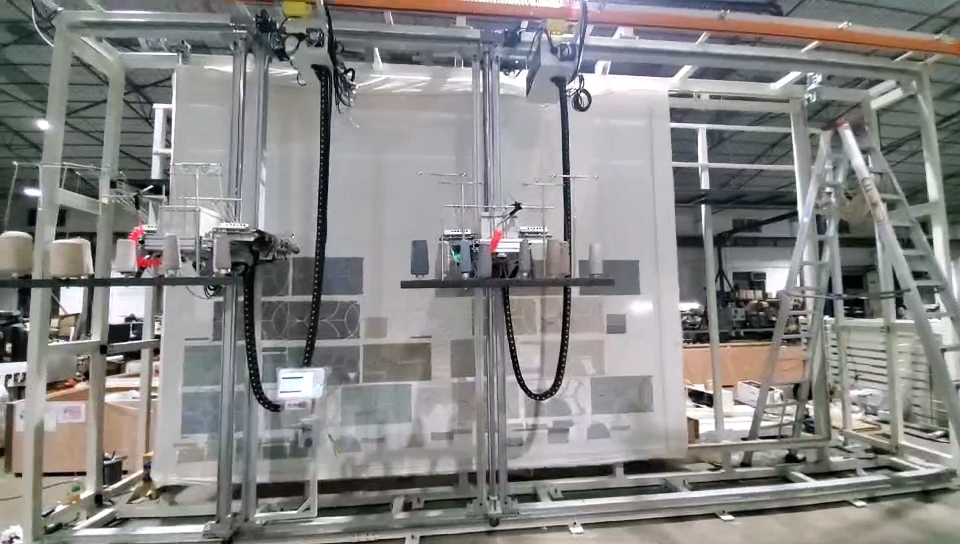

MIXC Textile Technology Co., Ltd.,a leading innovator in robotic tufting solutions, is proud to announce the successful customization of a Robotic Tufting Machine with 2 Y Axles in One System for an Indian carpet manufacturer. This project marks another milestone in MIXC’s mission to provide intelligent, efficient, and tailor-made automation solutions for the global textile industry.

The Indian customer approached MIXC with a clear requirement — to increase tufting production efficiency without sacrificing precision or quality. In response, MIXC’s R&D team designed and developed a Robotic Tufting Machine with 2 Y Axles in One System equipped with two tufting guns operating simultaneously, effectively doubling output capacity.

“Our goal was to help the client produce more carpets in less time, while maintaining the same level of accuracy and craftsmanship,” said a spokesperson from MIXC’s engineering department. “The dual-Y axis solution embodies our strength in mechanical design and software integration.”

Two robotic tufting guns working simultaneously to achieve dual production.

Each robotic arm can tuft approximately 1.8 m² of simple patterns per hour, resulting in 3.6 m²/hour combined productivity.

Retains the same precision positioning (±0.1mm/m), cut pile speed (up to 2000 stitches/min), and loop pile speed (up to 2500 stitches/min) as the standard MIXC model.

All core components and accessories are independently manufactured by MIXC for maximum reliability.

The software control system is fully developed in-house, ensuring seamless coordination between both tufting arms.

This customization not only showcases MIXC’s strong independent R&D capability, but also demonstrates the company’s commitment to customer-focused innovation. The result is a high-performance machine that allows manufacturers to produce two carpets simultaneously, significantly improving production efficiency and reducing operational costs.

At MIXC, innovation goes far beyond equipment design — it’s part of our company DNA.

As a technology-driven manufacturer, we combine mechanical precision, electronic control, and intelligent software to deliver complete robotic tufting solutions tailored to our customers’ specific production needs.

Independent R&D and Manufacturing:

All major components — from mechanical arms and servo systems to control panels and software — are developed and produced in-house, ensuring full system compatibility and exceptional quality control.

Customization Expertise:

From single-head to multi-axis robotic systems, MIXC provides flexible customization options for diverse carpet sizes, patterns, and production environments.

High-Precision Engineering:

Our robotic tufting machines offer ±0.1mm/m positioning accuracy, high-speed operation up to 2500 stitches per minute, and perfectly even pile surfaces across complex designs.

Intelligent Software Integration:

MIXC’s proprietary tufting software supports multiple file formats (DST, DSB) and automatically optimizes filling paths, reducing programming time and improving production efficiency.

Global Service Support:

With customers across Asia, Europe, and the Middle East, MIXC provides comprehensive technical consultation, installation guidance, and post-sale maintenance, ensuring stable performance and long-term reliability worldwide.

Through continuous technological innovation and customer collaboration, MIXC has become a trusted partner for carpet manufacturers seeking smarter, faster, and more precise tufting solutions.

The success of the Dual-Y Axis project reflects MIXC’s ability to respond rapidly to market demands and to lead the industry toward a more automated and intelligent future of carpet production.

MIXC Textile Technology — where innovation meets precision.

Contact Us Now!

Interested in customizing your own robotic tufting solution?

Our technical experts are ready to help you design the perfect system for your carpet production line.Phone: +86-18505106265

Email: info@mixc-tech.com