- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-18 Origin: Site

At MIXC Textile Technology Co., Ltd., every customer visit is an opportunity to demonstrate not only our advanced robotic tufting technology, but also our commitment to precision customization and customer satisfaction. Recently, a group of Japanese clients visited our factory with their own yarn and carpet design drawings for on-site sampling. The result was a perfect success, showcasing the strength of MIXC’s innovation and engineering expertise.

One of MIXC’s greatest advantages lies in our ability to design and manufacture tailor-made robotic tufting machines that meet the unique needs of different production environments. For this project, our engineers developed a special model with an effective tufting area of 5.5m (length) × 3.2m (height). This custom dimension was precisely calculated according to the client’s workshop size and production demands, ensuring maximum efficiency and space utilization.

Unlike standard equipment, MIXC machines can be flexibly designed in both working area and technical specifications, giving customers the freedom to produce carpets of varying scales and complexities without compromising on quality.

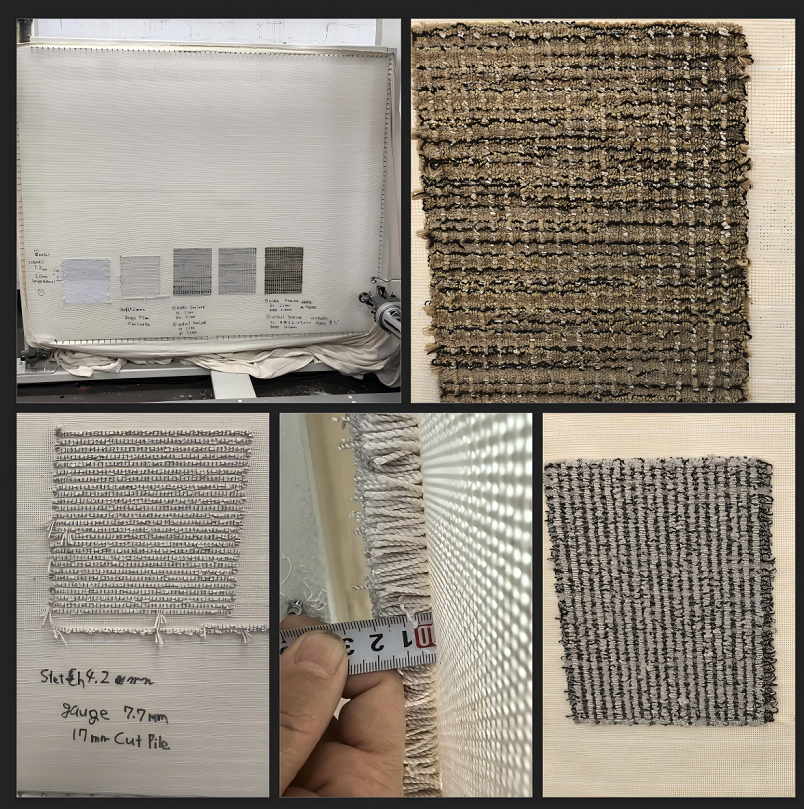

During the client’s visit, our technical team carried out a live tufting demonstration using the yarn and drawings provided by the customer. The robotic tufting machine executed the design with outstanding accuracy, delivering a sample that perfectly matched the client’s expectations in terms of pattern clarity, pile consistency, surface flatness, and overall texture.

The immediate success of the trial run reinforced the customer’s confidence in MIXC’s technology and proved that our machines can directly transform creative designs into high-end carpet samples within hours—something that traditional methods could not achieve with the same efficiency.

MIXC robotic tufting machines combine industrial-grade efficiency with artisan-level detail. The Japanese client witnessed firsthand how our equipment can achieve up to 2000 stitches per minute, while maintaining precise positioning accuracy of ±0.1mm/m. This enables the production of luxury, custom-designed hand-tufted carpets at a scale and speed previously unattainable.

With intelligent control systems, automated yarn detection, and flexible pile height adjustment, MIXC machines deliver a unique blend of speed, stability, and creativity. The finished samples reflected the premium quality expected for high-end custom rugs, confirming that our solutions are ideal for both artistic projects and commercial carpet production.

This successful collaboration with Japanese clients highlights MIXC’s growing influence in the global textile machinery market. By providing:

Customized machine dimensions to match specific workshop layouts,

On-site testing and sampling with client-provided materials,

Proven quality assurance through trial production,

we ensure that every international customer receives more than just equipment—they receive a reliable partner committed to their long-term success.

At MIXC, our philosophy of “Technology Creates Value” drives us to deliver robotic tufting solutions that combine innovation, precision, and efficiency. The successful Japanese case is not only a milestone for our company, but also a demonstration of how MIXC machines are enabling customers worldwide to enter a new era of high-end, customized carpet manufacturing.