- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-10 Origin: Site

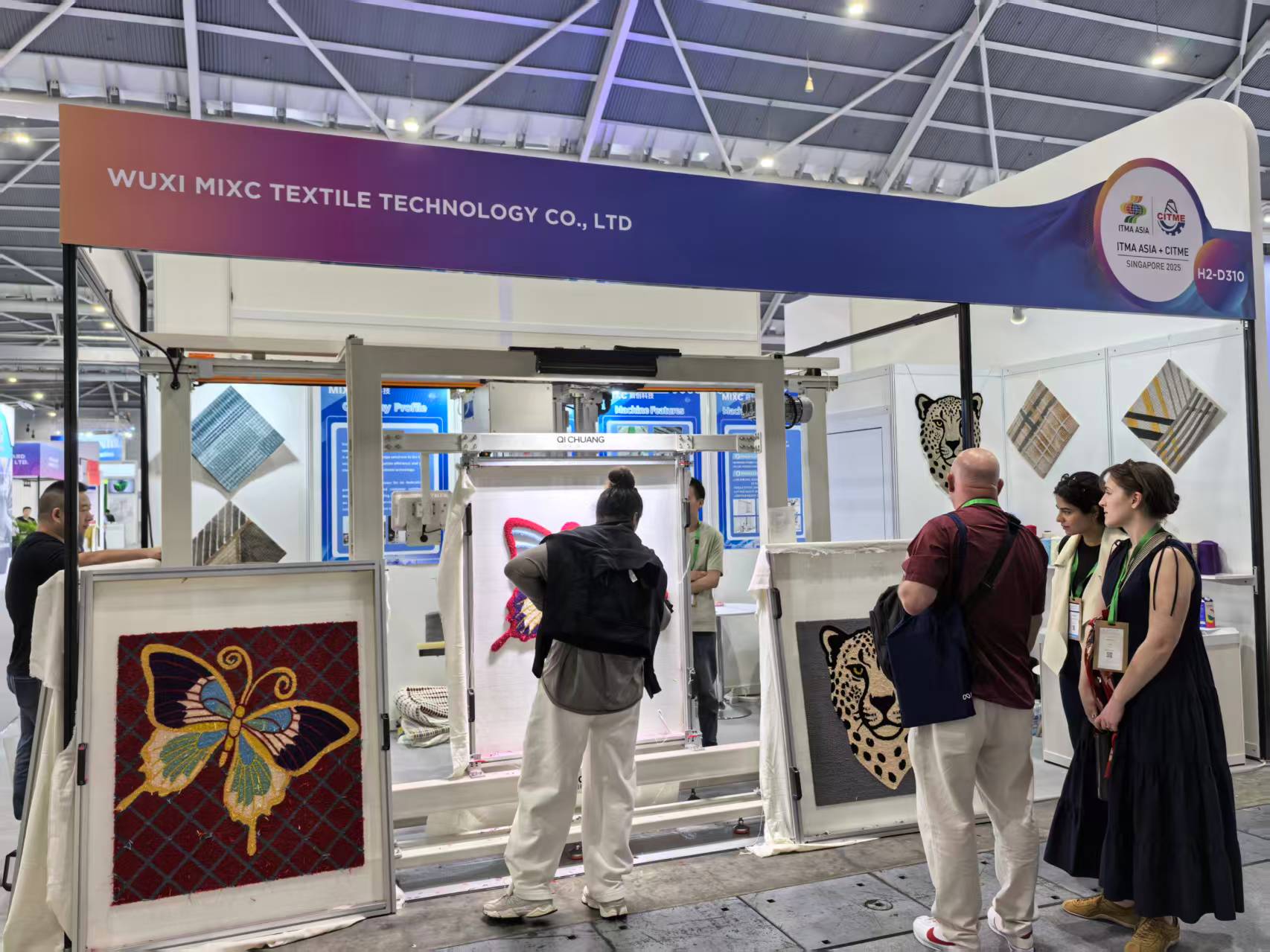

Singapore — October 31, 2025 – MIXC Textile Technology Co., Ltd., a leader in robotic tufting technology, concluded a successful showcase at ITMA ASIA + CITME 2025, held from October 28 to 31 at the Singapore Expo. At Booth H2/D310, MIXC demonstrated its cutting-edge robotic tufting machines, drawing attention from textile industry leaders, manufacturers, and innovators who witnessed firsthand the power of automation in transforming carpet and fabric production.

During the exhibition, MIXC’s robotic tufting machines captivated attendees with their outstanding performance and flexibility. Key highlights from the live demonstrations included:

Impressive Speed and Efficiency – The machines reached up to 2,500 stitches per minute for loop pile and 2,000 stitches per minute for cut pile, providing manufacturers with the ability to significantly reduce production time and increase output.

Unmatched Precision – The robotic tufting systems featured ±0.1mm repeat positioning accuracy, ensuring the highest level of precision in every design, whether for intricate patterns or large-scale productions.

Flexible Design Capabilities – Demonstrations showcased the ability to produce a variety of designs, including cut pile, loop pile, and high-low pile combinations. MIXC’s machines also displayed the versatility to create patterns in various directions and with multiple color configurations.

Intelligent Automation – Attendees were impressed by the automated yarn break detection, intelligent tension control, and automatic maintenance point return, ensuring the machines operated smoothly and with minimal downtime.

Innovative Design Software – The proprietary design software, supporting DST and DSB formats, allowed for seamless transitions from digital design to physical production, empowering designers and manufacturers to work efficiently and creatively.

The textile and flooring industries are increasingly looking for solutions that prioritize customization, sustainability, and production efficiency. MIXC’s robotic tufting machines meet these needs by:

Enhancing Customization: The machines offer high versatility in design, allowing manufacturers to create luxury carpets, bespoke rugs, and other artistic floor designs with precise accuracy.

Reducing Environmental Impact: With energy-efficient features, such as precise cloth tensioning and reduced material waste, MIXC’s machines align with the growing demand for sustainable manufacturing practices.

Streamlining Production: By reducing labor dependency and speeding up production cycles, the robotic tufting machines help manufacturers meet the growing demand for high-quality carpets while lowering operating costs.

In regions like Southeast Asia, where there is rapid growth in construction, interior design, and hospitality, MIXC’s solutions provide the ideal balance between innovation, efficiency, and sustainability, making them an essential choice for manufacturers looking to stay competitive in an ever-evolving market.

MIXC’s participation in ITMA ASIA + CITME 2025 also served as a key opportunity to foster new partnerships and expand its presence in Southeast Asia. During the event, MIXC:

Engaged with Local Manufacturers and Distributors: Strengthening ties with key industry players and establishing new distribution channels across the region.

Explored Collaborative Opportunities: Discussing the integration of robotic tufting machines into various textile applications, from large-scale carpet production to intricate, customized designs for luxury interiors.

Established Strategic Partnerships: MIXC is excited to collaborate with leading design studios and project developers to offer innovative flooring solutions for high-end residential, commercial, and hospitality projects.

With a growing footprint in Southeast Asia, MIXC is poised to further expand into Asia-Pacific markets, delivering its innovative tufting technology to meet regional demands.

What sets MIXC Textile Technology apart in the competitive landscape of textile machinery? Here’s why industry professionals are choosing MIXC for their robotic tufting needs:

Precision: Achieving unparalleled ±0.1mm repeat positioning accuracy for flawless design execution.

Speed: High-speed tufting heads that deliver 2,000–2,500 stitches per minute, significantly reducing production time.

Automation: Intelligent features like automated yarn break detection and tension control to ensure continuous operation without interruptions.

Quality: The combination of high-precision servomotors and advanced cloth-tensioning systems guarantees reliable, consistent performance.

Flexibility: Proprietary design software allows easy adaptation to various production needs and ensures smooth transitions from digital design to manufacturing.

As MIXC looks beyond ITMA ASIA + CITME 2025, the company is set to:

Expand Regional Support: Establish technical support centers across Asia-Pacific to provide faster service and specialized training.

Invest in R&D: Accelerate development in AI-driven patterning, multi-material tufting, and the next generation of automation technology.

Innovate Products: Launching tufting models tailored for both luxury and high-volume production markets, offering manufacturers even more options for customization and efficiency.

MIXC Textile Technology’s successful participation in ITMA ASIA + CITME 2025 reinforces its commitment to revolutionizing the tufting industry with intelligent automation, precision engineering, and sustainable practices. As the textile and flooring markets continue to evolve, MIXC stands at the forefront of helping manufacturers create high-quality, eco-friendly products with speed, efficiency, and unmatched design capabilities.

MIXC TEXTILE TECHNOLOGY CO., LTD.

Booth: H2/D310, ITMA ASIA + CITME 2025, Singapore Expo

Phone: +86-18505106265

Email: info@mixc-tech.com

Website: www.robotufter.com

Sales Office: RM1103-1, No.1688 Taihu west avenue, Binhu district 214062 Wuxi City, Jiangsu Province, China

Factory address: No. 3 Panjin Road, Jinsha South China Hardware Industry Base, Danzao Town, Nanhai District, Foshan City, Guangdong Province, China