- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-01-06 Origin: Site

In 2026, the demand for robotic tufting machines continues to rise as the textile industry embraces automation. These machines not only increase production efficiency but also provide high-quality, consistent tufting results that manual methods can't match. If you're considering investing in a robotic tufting machine, understanding its price is essential for making an informed purchase. This buyer’s guide will break down the factors that affect the price of robotic tufting machines, offer a price range for 2026, and help you choose the right machine for your business needs.

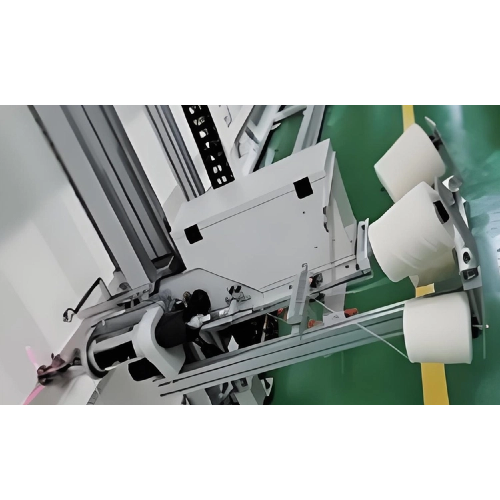

A robotic tufting machine is an automated textile machine used to insert yarn into fabric, creating tufted designs commonly seen in carpets, rugs, and upholstery. These machines use robotic arms or systems controlled by advanced software to perform precise tufting at high speeds. Unlike traditional manual tufting methods, robotic tufting machines are designed for mass production, ensuring efficiency, consistency, and the ability to handle complex patterns with minimal human intervention.

Automation: Robotic tufting machines are fully automated, meaning that they operate with minimal manual input, reducing labor costs and human error.

High Precision: These machines offer high precision in tuft placement, ensuring consistency across large batches of products.

Speed: Robotic tufting machines are capable of producing tufted textiles at speeds significantly faster than manual tufting, enhancing overall productivity.

Flexibility: They can handle a wide range of designs, from basic to highly intricate patterns, making them versatile for different types of textile production.

Software Integration: Robotic tufting machines come equipped with specialized software that allows for the customization of tuft patterns and the integration of design files, such as DST and DSB formats.

These features make robotic tufting machines an ideal solution for large-scale manufacturers seeking to optimize their production process and create high-quality tufted products.

The price of robotic tufting machines can vary widely depending on several key factors. These factors include machine specifications, automation levels, production capacity, material quality, and software integration. Let’s take a closer look at each of these factors.

Robotic tufting machines come with a variety of specifications that directly impact their price. Machines with larger production capacities, higher speeds, and more advanced features generally come with a higher price tag. Here are a few critical specifications that influence the cost:

Speed: Machines capable of tufting at faster speeds (e.g., 2000 stitches per minute or more) tend to cost more due to their increased productivity.

Design Complexity: Machines that can handle more intricate and custom designs require advanced software and higher precision, which increases the cost.

Production Capacity: The size and scale of the machine determine how much product it can produce in a given time. Larger machines designed for high-volume production are more expensive.

The level of automation integrated into the tufting machine plays a significant role in its price. Machines with full automation (including robotic arms and AI integration for precise tufting) will naturally cost more than machines with limited automation or manual intervention. Automation leads to higher production efficiency and reduced labor costs, which can offset the higher initial cost over time.

Fully Automated Systems: These machines are equipped with robotic arms and AI software to perform all tufting tasks autonomously.

Semi-Automated Systems: These machines may still require human operators to handle specific tasks but automate most of the tufting process.

The production capacity of a robotic tufting machine is an essential consideration for buyers. Larger machines designed to handle higher volumes of production will be priced higher. These machines can cater to the needs of large-scale manufacturers that require continuous operation and consistent output.

Large-Scale Machines: Designed for high-volume production, capable of producing a large number of products in a short period.

Small-Scale Machines: Suitable for smaller businesses or custom production, these machines typically have lower capacity and are priced more affordably.

Modern robotic tufting machines come with sophisticated software that allows operators to input design files and adjust settings for customization. The cost of the software is often bundled into the price of the machine, with more advanced software (supporting multiple file formats, real-time design adjustments, etc.) increasing the overall cost of the machine.

Design Software Compatibility: The ability to work with various design files like DST and DSB formats can impact the machine's price.

Customization Features: Machines that allow for real-time customization of tuft patterns, color options, and textures tend to be more expensive.

The build quality and materials used in a robotic tufting machine affect its price. Machines built with durable, high-quality materials can operate for longer periods with minimal maintenance. Additionally, these machines often come with warranties that cover the cost of repairs and spare parts.

High-End Materials: Machines made with top-tier components, such as advanced robotics, durable yarn-feeding systems, and robust mechanical parts, tend to have higher upfront costs but offer greater longevity and reliability.

Standard Materials: Machines made with more cost-effective components may have a lower price point but could require more maintenance in the long run.

In 2026, the price of robotic tufting machines varies depending on the model, specifications, and capabilities. Below is an approximate breakdown of the price range for different types of robotic tufting machines.

These are entry-level machines designed for small-scale production or businesses just starting with automated tufting.

Feature | Low-End Models |

Price Range | $50,000 - $100,000 |

Key Features | Basic automation, slower tufting speeds, limited design complexity |

These machines are ideal for businesses looking to test automation in a limited capacity or those with smaller production needs.

Mid-range machines offer a balance of advanced features and cost-effectiveness, making them ideal for growing businesses that require a mix of high-quality output and productivity.

Feature | Mid-Range Models |

Price Range | $100,000 - $200,000 |

Key Features | Faster speeds, better design customization, semi-automation |

These models offer more productivity and flexibility, allowing manufacturers to scale their operations while maintaining a reasonable investment.

High-end robotic tufting machines are designed for large-scale operations and feature the latest automation, precision controls, and advanced design capabilities.

Feature | High-End Models |

Price Range | $200,000 - $500,000+ |

Key Features | Full automation, extremely fast tufting speeds, high production capacity, full software integration |

These machines are built for high-volume, high-demand environments, providing maximum efficiency and minimal downtime.

While the price of the machine itself is the most significant cost, several other expenses need to be considered when purchasing a robotic tufting machine.

Most robotic tufting machines require professional installation and setup. Depending on the complexity of the machine and the location of your facility, these costs can vary.

Installation Service | Estimated Costs |

Basic Installation | $10,000 - $20,000 |

Full Setup and Testing | $20,000 - $30,000 |

Training your operators to use the robotic tufting machine efficiently is essential. Many manufacturers offer training packages, which may include on-site or virtual sessions.

Training Service | Estimated Costs |

Basic Training | $5,000 - $10,000 |

Comprehensive Training | $10,000 - $15,000 |

Routine maintenance and occasional repairs are necessary to keep your robotic tufting machine running smoothly. Some suppliers offer maintenance packages, which can help reduce the risk of costly repairs.

Maintenance Package | Estimated Costs |

Annual Maintenance | $5,000 - $15,000 |

Spare Parts | $5,000 - $10,000 annually |

As technology continues to advance, you may need to update the software that controls your robotic tufting machine to keep it compatible with new designs and functionality.

Software Upgrade | Estimated Costs |

Basic Upgrades | $2,000 - $5,000 |

Advanced Upgrades | $5,000 - $10,000 |

Selecting the right robotic tufting machine requires a clear understanding of your production needs, budget, and long-term business goals. Here are some key considerations when choosing a robotic tufting machine:

If you run a high-volume production facility, a machine with higher speed and larger production capacity will be necessary. On the other hand, if your business focuses on custom or small-batch production, you may want to prioritize design flexibility and customization options.

Given the significant investment involved, it’s essential to determine how much you’re willing to spend upfront and explore financing options if needed. Some manufacturers offer leasing or financing options to help with the initial investment.

When choosing a robotic tufting machine, consider how it will fit into your business’s future growth. A more expensive machine with high automation may offer long-term benefits by increasing production efficiency and reducing labor costs.

Working closely with trusted suppliers will ensure that you select a machine that meets your needs. Suppliers can help you understand the different models available, provide detailed pricing information, and offer insights into how each machine can optimize your business operations.

Leasing may be an attractive option if your business does not have the capital for a large upfront investment. Leasing allows you to use the equipment while preserving cash flow and providing flexibility if your business needs change. However, buying the machine outright gives you ownership and may offer better long-term value.

Many manufacturers provide financing options that allow you to pay for the machine in installments. This can help make a robotic tufting machine more accessible to small and medium-sized businesses.

Investing in a robotic tufting machine can provide substantial ROI by increasing production speed, reducing labor costs, and improving product consistency. It’s essential to calculate the expected ROI before making a purchase decision.

Choosing the right robotic tufting machine requires a clear understanding of the factors that influence its price and a machine that aligns with your business’s needs. Whether you're a small business aiming to scale up or a large manufacturer seeking to enhance production efficiency, robotic tufting machines offer a variety of solutions. At MIXC Textile Technology Co., Ltd., we provide a range of robotic tufting machines designed to meet different production capacities and budget requirements. By evaluating specifications, production volume, and long-term ownership costs, we can help you find the perfect machine that fits your business goals. Our expert team is available to guide you through every step, ensuring that you make an informed decision. Reach out to us today to explore our products and discover how we can support your business’s growth with cutting-edge tufting technology.

The price of a robotic tufting machine varies between $50,000 and $500,000+ depending on the model, features, and production capacity.

Key factors include machine specifications, automation levels, production capacity, software integration, and material quality.

Yes, costs for installation, training, maintenance, spare parts, and software upgrades should be considered when budgeting for a robotic tufting machine.

Match the machine’s capabilities with your production needs, budget, and long-term business goals. Consulting with a trusted supplier can also help ensure the best fit.

Yes, many manufacturers offer financing options, such as leasing or installment plans, to help businesses manage the cost of purchasing a robotic tufting machine.