- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-12-10 Origin: Site

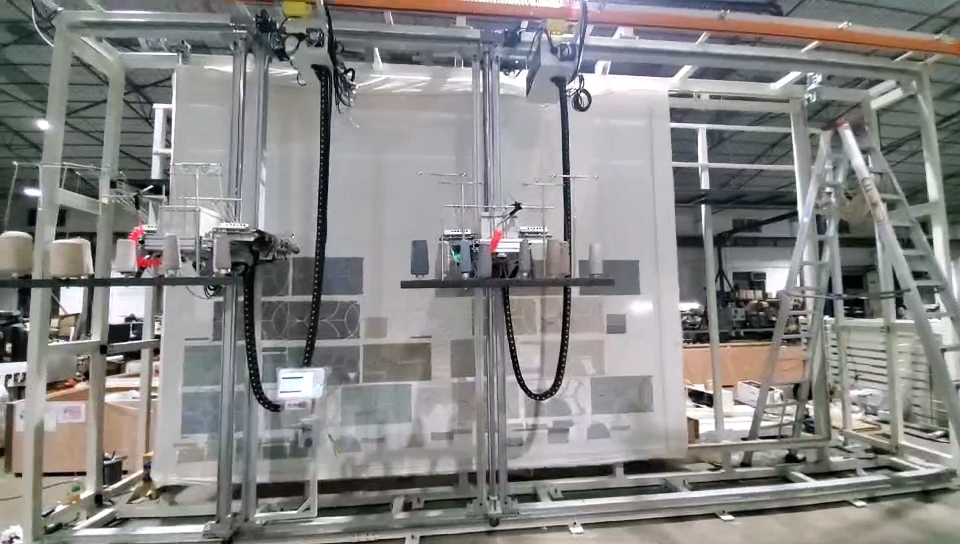

A robotic tufting machine lets you make carpets and fabrics quickly and accurately. MIXC TEXTILE TECHNOLOGY CO., LTD. is a top company with new technology. Automation in textile work helps you make better products faster. You can use less energy and keep up with what people want by using modern machines. This machine gives you steady results and works well every time.

Robotic tufting machines make carpets by themselves. This saves time and lessens hard work for people. These machines work very accurately. They make sure every carpet is made well. Using a robotic tufting machine lowers labor costs by up to 80%. It also cuts down material waste by 30%. MIXC's machines let you change designs easily. You can make special carpets without much trouble. Cleaning and oiling the machine often helps it work well. This also makes the machine last longer.

A robotic tufting machine is a new tool for making carpets and textiles. It works fast and makes things very exact. This machine puts yarn into fabric by itself. You do not need to do much by hand. It can make patterns and textures on its own. The machine uses designs that are programmed in, so every product looks the same.

You can see what a robotic tufting machine does in this table:

Core Function | Description |

|---|---|

Automation | The machine does the work of making yarn loops. You do not need to do as much by hand. |

Precision | It follows set patterns, so results are always the same. |

Speed and Efficiency | You can make textiles faster than old ways. This helps you get more done. |

Versatility | The machine can make many kinds of textiles. It works with different materials, so you can be creative. |

MIXC TEXTILE TECHNOLOGY CO., LTD. is a top company in this area. They make robotic tufting machines that help you get better results in less time. Their machines use robots, smart computer controls, and fast tufting heads. You can change needle spaces and find yarn breaks without stopping. These things make MIXC a good choice if you want to make textiles better.

Note: MIXC’s robotic tufting machine can go as fast as 2000 stitches each minute. You can use their special software to make your own carpet patterns.

Robotic tufting machines are different from traditional tufting machines in many ways. The table below shows how they compare:

Feature | Robotic Tufting Machines | Traditional Tufting Machines |

|---|---|---|

Automation Level | High | Low |

Manual Labor Requirement | Much Less | High |

Throughput | More | Less |

Yarn Loading | Automatic | By Hand |

Pattern Adjustment | Robotic Systems | By Hand |

Control Systems | Advanced Digital Control | Simple Mechanical Control |

Design Flexibility | High | Not Much |

Speed (RPM) | Up to 150 | Slower |

Precision Tolerance | ±0.1 mm | Not as exact |

With a robotic tufting machine, you get many benefits:

You do not have mistakes from people.

You follow the same rules for every item.

You work faster and make fewer errors.

You use smart digital controls for better results.

MIXC’s machines use servo motors and closed-loop control systems. You can trust these machines to give you the same results every time. Smart features like finding yarn breaks and changing patterns with a computer make MIXC better than old machines.

If you want your textile business to grow, a robotic tufting machine from MIXC TEXTILE TECHNOLOGY CO., LTD. helps you work faster, smarter, and with more ideas.

First, you get the robotic tufting machine ready to use. This helps the machine work well and keeps it safe. Here are the steps you should follow:

Collect your supplies. You need oil, a clean cloth, a small brush, and the manual.

Make sure your workspace is clean and has fresh air. Take away any dirt or trash from the machine.

Find the places on the machine that need oil.

Put a few drops of oil on each spot.

Turn on the machine for a short time. This spreads the oil everywhere it needs to go.

Wipe off any extra oil so it does not build up.

Store the machine the right way. Use the manual to know how to store it between uses.

Tip: Doing regular checks and setting the machine right helps it last longer. Always follow safety rules, like cleaning and knowing how to turn off the machine fast, to keep everyone safe.

You pick how your carpet or fabric will look by programming the robotic tufting machine. You use special computer software to make and send your designs. MIXC TEXTILE TECHNOLOGY CO., LTD. gives you software that works with DST and DSB files. This makes it easy to make your own carpet designs.

Here is a table with a popular design software:

Software Name | Description |

|---|---|

eDesigner | This is a pro tool for making, testing, and making carpets and rugs by hand, machine, print, or robot tufting |

You put your design into the computer. The machine reads the design and sets the needle spaces and tufting order. This lets you control how your finished carpet will look and feel.

The robotic tufting machine uses robots to make carpets fast and exact. You set things like stitch speed and pile height before you start. The machine uses sensors to watch each step and fix things if needed.

The machine lets you control tufting settings very well.

Sensors help the machine stay exact and stop mistakes.

The process is faster than doing it by hand, so you can make more.

You get good quality and fewer mistakes.

You can change tufting choices to fit what people want.

MIXC’s robotic tufting machine can go up to 2000 stitches each minute. The smart system finds yarn breaks and changes tension by itself. You get good results every time.

After tufting, you finish and check your carpet. The machine helps you look for problems and make sure every carpet is good.

You look at the carpet to see if it is even and the pattern is right.

The machine’s sensors tell you if there are problems, like yarn breaks or bad tension.

You can fix things or make repairs if you need to.

Good finishing makes your carpets look nice and last longer.

Note: MIXC’s robotic tufting machine has a system that finds breaks. This tells you about problems and helps you fix them fast, so your work goes smoothly.

You finish by packing and storing your carpets. With a robotic tufting machine, you make good textiles with less work and more steady results.

Automation helps you make more carpets faster. The MIXC robotic tufting machine uses robots to put yarn in place and make patterns. You set up the machine, and it works fast with little help from you. The tufting head moves quickly, so you finish carpets in less time. Look at how fast it can go:

Tufting Type | Maximum Stitch Speed (stitches/min) |

|---|---|

Cut Pile | 2000 |

Loop Pile | 2500 |

This speed lets you fill big orders and keep your business busy.

You get exact results each time you use the machine. MIXC machines use special technology to keep yarn in the right spot. This means you make fewer mistakes and waste less yarn. The machine copies patterns very well, so your carpets look great. You can count on the robotic tufting machine for fancy carpets.

Smart automation

Exact technology

High-quality carpets with little waste

Faster work

You can make lots of different designs and styles. MIXC machines let you change pile heights and switch between cut and loop pile without stopping the machine. The smart screen makes it easy to change settings. You can use many materials and add digital designs. This helps you make custom carpets or try new ideas fast.

Feature | Description |

|---|---|

Variable pile height tufting effects | Lets you pick different heights for cool designs. |

Non-stop cut – loop changeover | Switches styles quickly for more choices. |

Smart HMI operator interface | Easy controls for simple changes. |

Advanced and high speed tufting head | Makes hard designs fast. |

Fully compatible with eDesigner software | Adds digital designs for more ideas. |

You can change designs quickly and make custom carpets without extra work.

You use smart software to run the machine. MIXC made its own system to control both tufting arms. The software keeps the machine working well. You get tools like yarn break finding and tension control. The system works with DST and DSB files, so you can go from a computer design to a finished carpet easily.

Feature | Description |

|---|---|

Automated Yarn Break Detection | Finds yarn breaks and keeps the machine running. |

Intelligent Tension Control | Changes tension for the best results. |

Proprietary Design Software | Uses popular design files for easy carpet making. |

You spend less time fixing problems and more time making good carpets.

Robotic tufting machines are used in many places. Most of these machines make carpets and rugs. In 2024, carpets and rugs are 58.3% of the market. You can find these machines in homes, offices, and cars. The residential sector makes carpets and rugs for houses. The commercial sector needs strong floors for offices and stores. The automotive sector uses tufted textiles inside cars. These machines are used in North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

Carpets and Rugs

Residential Sector

Commercial Sector

Automotive Sector

Using a robotic tufting machine gives you many good things. You can work faster and make more items. You save money because you need fewer workers. The machine helps you use less material, so you waste less. You get high-quality carpets every time because the machine is very exact. Smart systems help you avoid stops and keep working.

Cost Savings Aspect | Description |

|---|---|

Labor Cost Reduction | You can cut labor costs by up to 80%. |

Material Wastage Reduction | You can reduce material waste by up to 30%. |

Feature | Benefit |

|---|---|

Increased efficiency | You make more carpets in less time. |

Reduced labor costs | You spend less on workers. |

Exceptional precision | You get consistent, high-quality products. |

Minimized interruptions | You keep production running smoothly. |

You should pick a machine that fits what you need. Make sure it works with your materials. Choose a strong machine that lasts a long time. Check if it can connect with your other machines. Make sure it can do many jobs and change settings easily. MIXC TEXTILE TECHNOLOGY CO., LTD. has machines you can change to fit your goals.

Factor | Description |

|---|---|

Material Compatibility | The machine should work with your chosen materials. |

Durability | Pick a machine that needs little maintenance and lasts long. |

Automation Potential | Find a machine that boosts your production speed. |

Selection and Integration | Make sure the machine fits into your current setup. |

Tip: Always check what you need before you choose a machine. MIXC can help you find the best one for your business.

You now know how a robotic tufting machine works. It is important in making textiles. MIXC TEXTILE TECHNOLOGY CO., LTD. gives you smart machines. These machines are fast and easy to control. You can make more carpets with less work. Your carpets will be high quality every time.

Pick MIXC if you want good results and smart machines.

Ask MIXC for help or a special solution.

Want to make better carpets? Contact MIXC TEXTILE TECHNOLOGY CO., LTD. today.

A robotic tufting machine makes carpets and textiles fast and exact. You can use it to make patterns and designs by itself. MIXC TEXTILE TECHNOLOGY CO., LTD. has machines that help you make carpets easily and with good results.

You finish carpets faster when you use MIXC’s machine. It can make up to 2,500 stitches every minute. Smart controls and yarn break detection help you save time and make fewer mistakes.

Yes, you can make your own carpet designs. MIXC’s machine works with DST and DSB files. You use their software to upload patterns and change pile height or style for special carpets.

You can make cut pile and loop pile carpets. MIXC’s machine lets you change styles fast. You can pick different pile heights and patterns for homes, offices, or cars.

You keep the machine working well by doing simple things. Clean it, oil it, and use the built-in detection system to stop problems. MIXC gives you help and guides to make maintenance easy.